The power output of an internal combustion engine is a crucial factor in determining its performance. Two of the most commonly used methods for measuring this power output are indicated power and brake horsepower.

First of all, when we say indicated power it is the total power produced within the cylinder in one complete cycle without considering any losses, and on the other hand, the amount of power available at the dynamometer is called brake power.

Let’s take a closer look at the difference between indicated and braking power.

Brake power is usually less than indicated power. The difference between indicated and brake power is called friction power.

The primary goal of Internal combustion engine design and development is to lower production costs while increasing efficiency and power output. In order to achieve the above task, engineers compare the engine-developed power in the engines in terms of output and efficiency.

Hence they have to test the engine and make measurements of relevant parameters that reflect the performance of the engine.

In general, the type and quantity of tests to be performed are determined by a variety of parameters.

These are:

- Indicated power

- Brake power

- Friction power

- Mechanical Efficiency

- Volumetric Efficiency

- Air-Fuel Ratio

- Thermal Efficiency

- Specific Fuel Consumption

- Exhaust Gas Emissions

- Noise

What Is Brake Power In An Internal Combustion Engine?

The brake power of an internal combustion engine is the power available at the crankshaft for doing useful work. It is also known as engine output power. The brake power of an internal combustion engine is measured by a dynamometer.

Swinging field type dynamometers are the most precise measuring dynamometers. Swinging field type dynamometers are the best precise measuring dynamometers. This method is simple than other processes.

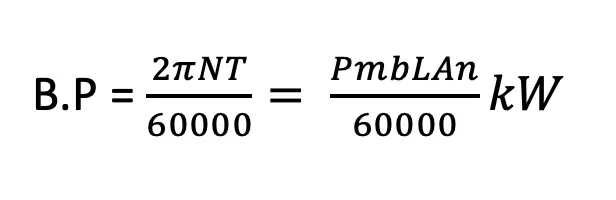

How To Calculate Brake Power

The brake power of an engine is usually measured on a dynamometer, which is a form of mechanical brake used to apply variable loads to a running engine so that torque and power may be calculated at different engine revolutions. Brake power formula:

Where,

T = W * R

W = Brake drum netload,

R = Brake drum effective radius, m

N = RPM of the crankshaft

T = Resisting torque, Nm

Pmb = Brake means effective pressure

Why Is It Called Indicated Power?

The power which is created inside the cylinder by the burning fuel is known as indicated power. It is the engine’s potential maximum output power.

The indicated power represents the total power available from the expansion of the gases in the cylinders, excluding any friction or heat, or losses in the system.

The indicated power is the total power available from the expansion of the gases in the cylinders, excluding any friction, heat, or any other losses in the system. This power is transmitted to the shaft by the connecting rod- crankshaft mechanism. There are some transmission losses, which are indicated by the mechanical efficiency of the engine.

Suppose the engine’s mechanical efficiency is 90%, and the indicated power is 9810kw. Power available at shaft = Indicated power * mechanical efficiency or, brake power = 9810*0.9 = 8829 kW

How Do You Find The Indicated Power?

Indicated power of an engine can be measured by using the indicator diagram or power card diagram. The indicated diagram can be used to determine an engine’s indicated power.

The performance of each cylinder unit of an engine is accessed using this diagram. The total power produced by the engine is the sum of the powers produced by each cylinder.

An indicator diagram is recorded on ships using a special instrument called an indicator instrument which consists of a small piston locked within a cylinder acting against a calibrated spring.

All primary forms of indication diagrams used to study and correct engine parameters can be drawn with the instrument. This can then be used to calculate the engine’s total power output, as well as its compression pressure, peak pressure, and efficiency.

Similarly, any divergence in the diagram alerts us to any fuel injection irregularities or running gear problems. The indicator instrument is positioned on the indicator lock with its drum in phase with the piston movement in order to measure.

The Indicator Diagram illustrates the variation of cylinder pressure; concerning the piston movement. The area of the diagram is calculated using a planimeter/ Plato meter and then multiplied by the cylinder constant and the engine speed.

Indicated Power is calculated by finding the actual mean effective pressure.

Actual mean effective pressure, Pm = sa/l N/m2

Where,

a = Area of the cylinder’s cross-section m2

I = The indicator diagram’s base width in cm

S = The spring value of the indicator’s spring, N/m2/cm

I.P = PmLAn/6000 kW

Where,

Pm = Mean effective pressure N/m2

L = Length of stroke, m

A = m2 = Area of the cylinder’s cross-section

N = RPM of the engine crankshaft

n= N/2 (for 4-stroke engine)

n= N (for 2-stroke engine)

Indicated power is directly proportional to

- Length of stroke

- Mean effective pressure

- Area of the bore of each cylinder

- Rotation per minute ( when the speed of an engine increases then indicated power is also increased)

Frictional Power/ Difference Between Indicated Power And Brake Power

Frictional power is the power loss in overcoming the friction between piston and cylinder walls, pump exhaust out and fresh charge air into the cylinder, between the crankshaft and camshaft and their bearing, etc.

Brake power is always less than indicated power because some losses occur when power transmits from the cylinder to the crankshaft, and this loss of power is called friction power. Frictional power is the difference between indicated power and brake power and calculates the losses in the internal combustion engine.

F.P (Frictional power) = I.P – B.P. (Indicated power – brake power)

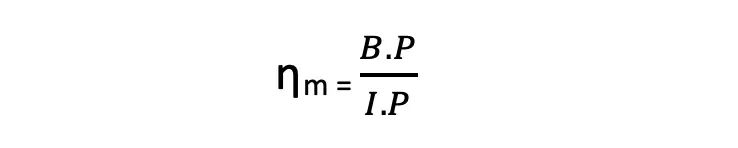

What Is The Mechanical Efficiency Of A Diesel Engine?

The mechanical efficiency of a diesel engine is a measure of the engine’s mechanical best ability to transport power generated in the cylinder to the crankshaft.

It is defined as the ratio of brake power to indicated power of the engine,

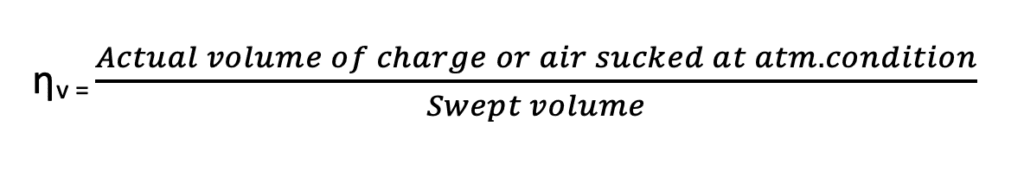

What Is The Volumetric Efficiency Of A Diesel Engine?

The engine’s breathing ability is measured by volumetric efficiency. It should be remembered that the engine’s power output is determined by how well it uses air.

The engine air Intake system must be designed in such a way that the engine must be able to take in as much air as possible.

Volumetric efficiency is defined as the ratio of the actual volume flow rate of air into the intake system to the rate at which the volume is displaced by the system.

Leave a Reply