The need to provide an efficient cargo hold ventilation system on ships to ensure the quality of transported items is critical. Such a system is required to minimize the formation of condensation in cargo spaces, remove potentially hazardous gases, and lower the detrimental heating of cargo being transported.

An efficient cargo hold ventilation system, therefore, prevents ship and cargo sweat, supplies fresh air to cargo being transported, and removes the smell from cargoes that might otherwise taint susceptible cargoes.

It also prevents the build-up of poisonous gases and gets rid of heat and moisture given out by some types of cargo.

Although the correct ventilation system onboard ships can keep cargo in good condition and prevent damage, there is no system yet that can prevent damage if the ship’s officers don’t know when and how to use it. This article provides a broad overview of the key concepts that underlie cargo ship ventilation systems and the ventilation techniques applied to cargo ships.

What is Shipboard Cargo Hold Ventilation?

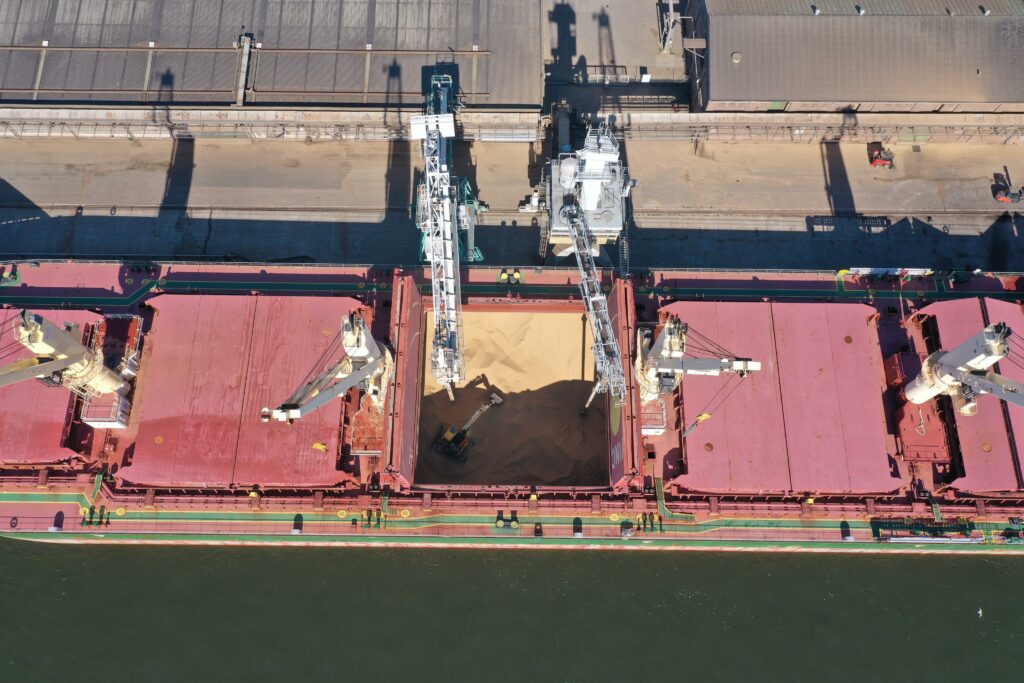

Shipboard cargo hold ventilation is the process of delivering fresh air to the cargo hold of a ship and removing any stale air or gas. This is done using a system of fans, ducts, and vents. Cargo holds ventilation is vital for two main reasons: to prevent the build-up of dangerous gases and to control temperature and humidity levels in the hold, both of which can affect the quality of the cargo.

Proper ventilation and temperature control of cargo holds are essential for preserving the cargo. Many types of cargo, such as foodstuffs and pharmaceuticals, are perishable and can be easily damaged by heat, cold, or poor air quality. By ensuring that the cargo hold is properly ventilated, ship operators can help to minimize the risk of cargo damage and avoid unnecessary cargo claims.

There are two main types of cargo hold ventilation: natural and mechanical. Natural ventilation relies on the wind and the ship’s movement to produce airflow, while mechanical ventilation uses fans to force air into the hold. Both methods have their advantages and disadvantages, and the best approach for a particular ship will depend on several factors, including the type of cargo being carried and the weather conditions.

Shipboard Ventilation Requirements.

Although installing appropriate ventilation systems on ships is of the utmost importance for all types of cargo, the specific kinds of ventilation that are necessary for different cargoes can vary greatly. Ventilation might be required, for instance, to get rid of odors that might taint sensitive cargoes, dissipate gas, cut down on condensation, and/or take away heat from the cargo.

A new guidance document from the Standard Club, INTERCARGO, and DNV GL helps masters with practical recommendations and better understand how to mitigate these risks by ensuring proper ventilation.

ventilation.

Heat can be generated from a variety of sources, including fruit, wet hides, insects such as weevils, and materials that are prone to spontaneous combustion.

It may be necessary to discharge combustible and explosive gases, such as those produced by coal, vehicle exhausts on Ro-Ro ships, carbon dioxide, and ethylene from ripening fruits and vegetables.

Not all cargoes require or even benefit from ventilation, for example, if a ventilation system in a bulk carrier is only installed for surface ventilation it can only remove and replace air on the surface of the cargo stow and will practically have no effect whatsoever should there be pockets of moisture in the stow.

Ship sweat and cargo sweat are the two most common types of condensation. When the sea temperature drops and lowers the nearby metal’s temperature below the dew point of the surrounding air, the former phenomenon manifests as beads of moisture condensing on the ship’s metalwork.

Similar to this, when the temperature of the cargo is lower than the dew point of the surrounding air, cargo sweat develops on the surface of the cargo. Therefore proper observation of sea, air, and cargo temperature is vital during the voyage as well as understanding the nature and properties of hygroscopic or non-hygroscopic cargoes.

The Main Types of Shipboard Ventilation Systems.

Whether natural or mechanical, a ventilation system that is well designed aims to induce a constant circulation of air throughout the holds and the mass of cargo.

This is accomplished so that the heat, moisture, fumes, vapors, gases, and odors that are given off by the cargo are discharged into the open air and replaced by air with a dew point that is suitable to the conditions that are currently in place.

There are generally three types of ventilation systems in use today:

- The natural ventilation of standard cargo compartments may sometimes be augmented by modified mechanized air circulating systems.

- The system for controlling the temperature that involves circulating air in insulated compartments in order to regulate both the temperature of the air and the amount of carbon dioxide that is released by specific goods.

- The use of mechanical ventilation in the cargo areas and regulating humidity within the compartment.

Most of these different kinds of mechanical ventilation are based on the same basic idea, which is to lower the dew point of the air in the ship’s compartments by dehumidifying to the point where it is impossible for ship or cargo sweat to form.

In the holds, there is little effort made to alter the temperature condition because the primary focus is on maintaining tight control over the dew point of the air that is around the cargo.

When used appropriately, effective ventilation can preserve goods in good condition in the vast majority of situations. If the ship’s officers don’t know when to use it or when not to, no ventilation system will be able to prevent cargo damage.

Additionally, the cargo must be properly stowed considering the numerous commodity classes that make it up, as well as dunnage and positioned in order to ensure that the ventilation reaches all relevant parts of the cargo.

Ventilation Guidelines.

If the dew point of the air is lower than the dew point of the cargo space, then ventilation should be turned on. The changing air will provide ventilation for the cargo area, and there should be only a minor risk of condensation occurring.

If the dew point of the air outside is higher than the temperature of the cargo, ventilation should be restricted. If ventilation were to take place under these circumstances, there is a risk that condensation may form on the cargo since the inside air will be exposed to air from the outside with a higher dew point.

When the vessel is equipped with a mechanical ventilation system, the air within the cargo compartment ought to be recirculated when there is a restriction placed on the intake of fresh air from the surrounding environment.

Despite this recommendation, special attention must, of course, be paid to conditions in which cargoes are emitting fumes, etc., and where ventilation may be necessary despite the likelihood of condensation under certain circumstances.

It should always be the goal to avoid stowing cargo that requires different ventilation treatment within the same compartment, if at all possible. In a similar manner, two compartments that need distinct types of ventilation should be effectively separated from one another.

Conclusion.

The importance of maintaining a dry ship and dry cargo at all times cannot be emphasized enough. The shipmaster must have a thorough understanding of the history of the goods that are delivered to his charge as well as the condition in which they are received, in order to protect the ship from claims.

The cargo must be protected from any unfavorable exposure to temperature and moisture from the point of origin to the delivery.

The Carriage of Goods by Sea Act (GOGSA) requires the shipowner to see to it that the shipmaster makes the holds, refrigerating and cool chambers, and any other areas of the ship in which goods are carried, fit and safe for their reception, carriage, and preservation. Therefore, ventilation considerations are crucial to this work.

Leave a Reply