Carriage of the cargo by sea transport starts with planning and searching for an appropriate cargo vessel and the cargo stowage factor plays a crucial role in this process. A ship must be fit for each cargo and cost-effective to keep a trade beneficial for all parties.

Here is my simple cargo stowage factor calculator:

Stowage Factor Calculator

| Cbm/MT Cub ft/MT | |

|

|

Calculate Volume Calculate Weight |

A smaller ship will lead to remaining in load port, a dead freight letter, or a new voyage, but a larger ship will remain just partly loaded at much higher freight costs.

Shippers, consignees, and brokers must be confident that they will charter the most suitable ship for exact cargo delivery that is where knowing the accurate storage factor of bulk cargo becomes critical.

What Is A Cargo Stowage Factor?

The stowage factor is the coefficient that indicates how much space is needed to load a unit mass onboard the ship or loading area in a port or at a warehouse. In the imperial system of measurements, the coefficient displays cubic feet for one long ton, and in the metric system, the space in cubic meters for one metric ton.

Knowing the stowage factor allows the cargo officer onboard the vessel, operator, and broker to calculate space in the ship’s cargo hold used by the cargo parcel or the minimum required volume of the cargo hold required for the shipment.

Despite the importance of the stowage factor, for most types of cargo, it remains an estimated value and should be used with caution, unless it is confirmed by production specification or historical data from the exact shipper.

A good example of the deviation of the stowage factor will be all kinds of grains that strongly depend on the humidity, which can be calculated to average, but practically varies depending on the number, time, and place of sampling.

If the stowage factor is precisely calculated or confirmed by the laboratory, the shape of the cargo hold, the number of bulkheads, and frames, and the way of loading the cargo by shippers or stevedores can have an impact on the final stowage factor or volume used by cargo.

How to Calculate the Stowage Factor?

Both the Imperial and Metric systems are used in cargo calculation on board the ships, cargo specifications, and documents, therefore you should pay attention to the measurements used.

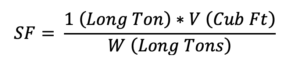

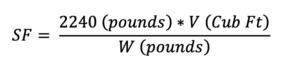

Cargo Stowage Factor Formula in Cub ft.

If you are using the Imperial system, one long ton, or 2,240 pounds, multiply the volume in cubic feet and divide by the cargo weight into long tons or pounds accordingly to find the stowage factor, which is the number of cubic feet required for stowing one long ton of specific cargo.

Please note that there is used a long ton, which is 2240 pounds, not a metric ton which is 2,204.6 pounds. One long ton is exactly 1.0160469088 metric tons and vice versus approximately 0.9842065276 long tons.

For example, if cargo has a volume of 30 cubic feet and a weight of 1700 pounds. The stowage calculation is 2,240 pounds times 30 divided by 1700. The stowage factor works out to 39.53 cubic feet per long ton.

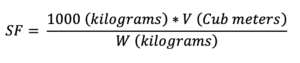

Cargo Stowage Factor Formula In Cubic Meters.

If you are using a metric system, the formula is 1,000 kilograms times the volume in cubic meters divided by the cargo weight in kilograms.

It is important to note that the stowage factor can be used as a combination of cubic feet per metric ton and therefore you might need to convert the stowage factor to corresponding measurements. Here comes in handy keeping conversion formulas or conversion tables ready for use.

Conversions Of The Stowage Factor From Cub Ft To Cbm.

1 Cubic meter equals 35.3147 Cubic feet.

If you need to convert the known stowage factor from cubic feet to cubic meters divide the storage factor by 35.3147.

For the opposite calculation from cubic meters to cubic feet multiply by 35.3147.

Here Is The Conversion Table For The Most Usable Range From 20 To 75 Cub Ft

| Cub Ft / Long Ton | Cbm / LT | Cbm / MT |

|---|---|---|

| 20 | 0,57 | 0,56 |

| 21 | 0,59 | 0,59 |

| 22 | 0,62 | 0,61 |

| 23 | 0,65 | 0,64 |

| 24 | 0,68 | 0,67 |

| 25 | 0,71 | 0,70 |

| 26 | 0,74 | 0,72 |

| 27 | 0,76 | 0,75 |

| 28 | 0,79 | 0,78 |

| 29 | 0,82 | 0,81 |

| 30 | 0,85 | 0,84 |

| 31 | 0,88 | 0,86 |

| 32 | 0,91 | 0,89 |

| 33 | 0,93 | 0,92 |

| 34 | 0,96 | 0,95 |

| 35 | 0,99 | 0,98 |

| 36 | 1,02 | 1,00 |

| 37 | 1,05 | 1,03 |

| 38 | 1,08 | 1,06 |

| 39 | 1,10 | 1,09 |

| 40 | 1,13 | 1,11 |

| 41 | 1,16 | 1,14 |

| 42 | 1,19 | 1,17 |

| 43 | 1,22 | 1,20 |

| 44 | 1,25 | 1,23 |

| 45 | 1,27 | 1,25 |

| 46 | 1,30 | 1,28 |

| 47 | 1,33 | 1,31 |

| 48 | 1,36 | 1,34 |

| 49 | 1,39 | 1,37 |

| 50 | 1,42 | 1,39 |

| 51 | 1,44 | 1,42 |

| 52 | 1,47 | 1,45 |

| 53 | 1,50 | 1,48 |

| 54 | 1,53 | 1,51 |

| 55 | 1,56 | 1,53 |

| 56 | 1,59 | 1,56 |

| 57 | 1,61 | 1,59 |

| 58 | 1,64 | 1,62 |

| 59 | 1,67 | 1,64 |

| 60 | 1,70 | 1,67 |

| 61 | 1,73 | 1,70 |

| 62 | 1,76 | 1,73 |

| 63 | 1,78 | 1,76 |

| 64 | 1,81 | 1,78 |

| 65 | 1,84 | 1,81 |

| 66 | 1,87 | 1,84 |

| 67 | 1,90 | 1,87 |

| 68 | 1,93 | 1,90 |

| 69 | 1,95 | 1,92 |

| 70 | 1,98 | 1,95 |

| 71 | 2,01 | 1,98 |

| 72 | 2,04 | 2,01 |

| 73 | 2,07 | 2,03 |

| 74 | 2,10 | 2,06 |

| 75 | 2,12 | 2,09 |

Conversions of the Stowage Factor from Long Tons to Metric Tons.

One long ton is exactly 1.0160469088 metric tons.

If you need to convert the known stowage factor from metric tons to long tons divide the storage factor by 1.016.

For the opposite calculation from long tons to metric tons multiply by 1.016.

Here Is The Conversion Table For The Most Usable Range From 0,50 To 2,50 Cbm/lt

| Cbm / Long Ton | Cbm / MT | Cub ft/ MT |

|---|---|---|

| 0,50 | 0,49 | 17,38 |

| 0,55 | 0,54 | 19,12 |

| 0,60 | 0,59 | 20,86 |

| 0,65 | 0,64 | 22,59 |

| 0,70 | 0,69 | 24,33 |

| 0,75 | 0,74 | 26,07 |

| 0,80 | 0,79 | 27,81 |

| 0,85 | 0,84 | 29,54 |

| 0,90 | 0,89 | 31,28 |

| 0,95 | 0,94 | 33,02 |

| 1,00 | 0,98 | 34,76 |

| 1,05 | 1,03 | 36,50 |

| 1,10 | 1,08 | 38,23 |

| 1,15 | 1,13 | 39,97 |

| 1,20 | 1,18 | 41,71 |

| 1,25 | 1,23 | 43,45 |

| 1,30 | 1,28 | 45,19 |

| 1,35 | 1,33 | 46,92 |

| 1,40 | 1,38 | 48,66 |

| 1,45 | 1,43 | 50,40 |

| 1,50 | 1,48 | 52,14 |

| 1,55 | 1,53 | 53,88 |

| 1,60 | 1,57 | 55,61 |

| 1,65 | 1,62 | 57,35 |

| 1,70 | 1,67 | 59,09 |

| 1,75 | 1,72 | 60,83 |

| 1,80 | 1,77 | 62,57 |

| 1,85 | 1,82 | 64,30 |

| 1,90 | 1,87 | 66,04 |

| 1,95 | 1,92 | 67,78 |

| 2,00 | 1,97 | 69,52 |

| 2,05 | 2,02 | 71,26 |

| 2,10 | 2,07 | 72,99 |

| 2,15 | 2,12 | 74,73 |

| 2,20 | 2,17 | 76,47 |

| 2,25 | 2,21 | 78,21 |

| 2,30 | 2,26 | 79,94 |

| 2,35 | 2,31 | 81,68 |

| 2,40 | 2,36 | 83,42 |

| 2,45 | 2,41 | 85,16 |

| 2,50 | 2,46 | 86,90 |

How To Use The Stowage Factor?

In shipping, the stowage factor is used as the primary tool for planning the cargo stowage onboard the vessel. Knowing the stowage factor and total weight of the cargo scheduled for loading defines the minimum volume of the cargo compartment for this cargo.

Vessel particulars contain this information reading a total volume of cargo holds and their distribution between cargo holds tween decks or positions of bulkheads available on the vessel.

For example, if you intend to ship 2000 metric tons of wheat with a stowage factor of 44 cub ft./mt, then you will require a coastal bulker with a total capacity of the holds 88000 or more, or one or more cargo holds on larger bulkers with this capacity depending on the sea route and port facilities in both ports.

Vessels are often designed for specific trade depending on the order of the client for their specific needs. Over time main trade routes or even shipowners are changed, but the ship’s hold capacity and deadweight remain the same. One of the main tasks of the ship’s operator is to find cargoes and voyages with the most effective load and therefore profit. The optimal stowage factor for each ship differs but can be easily calculated using hold capacity and summer and winter deadweights.

Now it becomes clear, that from an economic viewpoint there are light and heavy cargoes for each vessel defined by the stowage factor.

Light cargo is called once the ship’s cargo hold is fully occupied, but deadweight is not used.

Heavy cargo uses the full deadweight of the vessel before the ship’s cargo hold capacity is fully occupied.

Heavy cargoes are easier for handling cargoes both for chartering and for the ship’s crew for loading. It is easier to negotiate sales prices when full ships deadweight is in use, as light cargoes will require negotiating a higher rate per ton, as full cargo hold capacity will be used not reaching vessel deadweight.

From the perspective of the master and cargo officer, lighter cargos limit cargo distribution inside the cargo holds in order to remain to save trim and in some cases will require leaving empty space in the forward or aft part of the hold depending on the current vessel stability calculations.

You can calculate the stowage factor for any cargo including general cargo and even liquid cargo, but it is most often used for bulk cargo. Stowage factors for the most common and popular cargoes are presented in the following table.

List of Stowage Factor – Grains

| Cargo / Commodity Name | Cub ft/MT | Cbm/MT |

|---|---|---|

| Barley | 52 – 55 | 1,47 – 1,56 |

| Bran rice | 62 – 65 | 1,76 – 1,84 |

| Buckwheat | 54 – 57 | 1,53 – 1,6 |

| Coconut | 140 | 3,96 |

| Cogora pellets | 63 | 1,78 |

| Corn | 51 – 54 | 1,45 – 1,53 |

| Coweas | 44 – 45 | 1,28 – 1,30 |

| Linseed | 55 – 56 | 1,56 – 1,58 |

| Locust beans | 84 – 90 | 2,38 – 2,55 |

| Maize East Africa | 50 – 52 | 1,42 – 1,47 |

| Millet | 45 – 51 | 1,27 – 1,44 |

| Oats | 66 – 67 | 1,87 – 1,89 |

| Palm kernels | 58 | 1,64 |

| Peanuts husked | 105 – 110 | 2,97 – 3,11 |

| Peanuts not peeled | 106 – 131 | 3,00 – 3,70 |

| Potatoes | 50 – 55 | 1,42 – 1,56 |

| Raw sugar | 45 – 51 | 1,27 – 1,44 |

| Rice bran pellets | 52 – 60 | 1,47 – 1,7 |

| Rye | 48 – 52 | 1,36 – 1,47 |

| Soybeans | 56 – 58 | 1,58 – 1,64 |

| Sugar beet pulp pellets (SBPP) | 55 – 65 | 1,56 – 1,84 |

| Sunflower seeds | 64 – 69 | 1,81 – 1,95 |

| Wheat | 45 – 50 | 1,27 – 1,42 |

List of Stowage Factor – Raw material and Ores

| Cargo / Commodity Name | Cub ft/MT | Cbm/MT |

|---|---|---|

| Ammonium sulphate | 42 – 45 | 1,19 – 1,27 |

| Bauxite | 30 – 33 | 0,85 – 0,93 |

| Cake | 46 – 65 | 1,3 – 1,84 |

| Carbon / anthracite | 45 | 1,27 |

| Cast iron | 10 | 0,28 |

| Cement | 29 | 0,82 |

| Chinese clay | 46 | 1,3 |

| Clay | 25 – 30 | 0,7 – 0,84 |

| Coal | 47 – 55 | 1,33 -1,56 |

| Cobalt | 20 | 0,57 |

| Copper concentrate | 20 – 22 | 0,56 – 0,63 |

| Copra | 83 – 98 | 2,35 – 2,77 |

| Dolomite | 21 – 25 | 0,60 – 0,70 |

| Ferro-se | 25 | 0,7 |

| Ferrochrome | 15 | 0,42 |

| Fertilizers | 41 | 1,15 |

| Fish meal (anchovies) | 57 – 73 | 1,61 – 2,07 |

| Graphite | 20 – 35 | 0,57 – 0,99 |

| Gravel | 23 | 0,65 |

| Guanan | 42 – 44 | 1,19 – 1,25 |

| Gypsum | 24 – 28 | 0,67 – 0,78 |

| Iron ore in Sierra Leone | 25 – 29 | 0,71 – 0,82 |

| Kainit | 35 – 37 | 0,99- 1,05 |

| Kaolin | 40 | 1,13 |

| Kuanite | 25 – 30 | 0,7 – 0,84 |

| Limestone | 24 – 30 | 0,67 – 0,84 |

| Magnesite fine | 16 | 0,45 |

| Magnesite Klinker | 60 | 1,7 |

| Manganese | 25 – 30 | 0,7 – 0,84 |

| Phosphate | 23 – 30 | 0,65 – 0,85 |

| Phytophylitis | 30 | 0,84 |

| Pitch | 48 | 1,36 |

| Potash nitrate | 36 | 1,02 |

| Potassium nitrate | 36 | 1,02 |

| Potassium sulfate | 44 | 1,26 |

| Pyridine | 30 – 35 | 0,85 – 0,99 |

| Salt | 35 – 40 | 0,99 – 1,13 |

| Sand | 23 – 25 | 0,65 – 0,71 |

| Soda nitrate | 26 | 0,74 |

| Sorghum | 59 | 1,67 |

| Stone | 49 | 1,39 |

Leave a Reply