Shipboard cargo damage can occur for several reasons. These include accidents caused by moisture, flooding, or rainwater.

Moisture damage, however, is one of the most prevalent causes of cargo damage and a major source of cargo claims, for a variety of reasons. On ships, moisture that causes cargo damage is referred to as “sweat.”

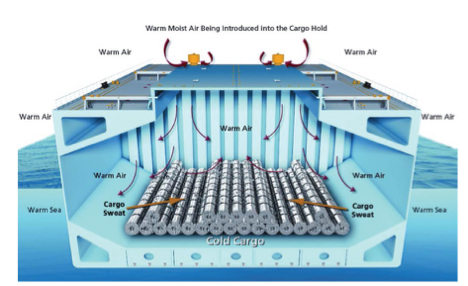

Sweat is formed when the water vapor in a parcel of air condenses out into visible water droplets. This occurs when the air is cooled below its dew point. The water droplets may be deposited either onto the structure of the ship or on the cargo. If the former occurs, it is known as ship sweat and this may run down or drip onto the cargo. The latter is known as cargo sweat.

The interaction between the dew point temperature of a parcel of air and the temperature of its surroundings is what influences the formation of sweat. In this blog post, these relationships and the factors that influence the dew point temperature are explained, as well as the methods used for determining the dew point of the air mass.

The Dew Point Temperature.

Air at a particular temperature contains water vapor, which is invisible. The higher the temperature of the air mass, the greater the volume of water vapor it can hold. This is referred to as the relative humidity of the air mass. As the temperature falls, the ability of the air mass to contain water vapor in an invisible form reduces, that is, its relative humidity (RH) falls.

Finally, a temperature is reached at which point the mass becomes saturated with water vapor, i.e., it can no longer hold the water vapor in an invisible state–the RH becomes 100%. The excess water vapor then condenses out into visible water droplets. This temperature is known as the dew point of the parcel of air.

Measuring Dew-point Temperature on Board Ships.

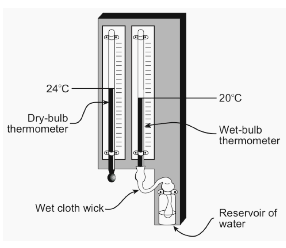

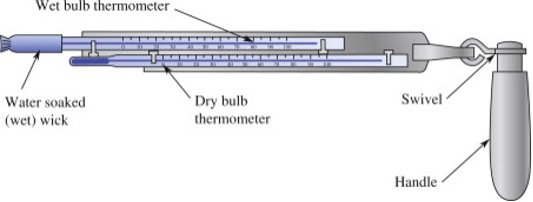

The dew-point temperature is measured on board ships using a wet and dry bulb thermometer or a sling psychrometer. A normal dry bulb is used to measure the dry air temperature. The wet-bulb thermometer is a dry bulb thermometer whose bulb is covered with a wick that is immersed in a reservoir of water.

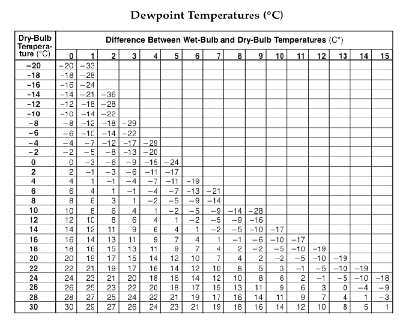

When in use, a dry bulb temperature is read and also a wet-bulb temperature. The difference between the two temperatures is referred to as the wet-bulb depression. Entering a Dew-point Temperatures ESRT chart with the dry bulb temperature on the side and the wet-bulb depression on the top will give the dew-point at where the two readings intersect.

The accuracy of the dew point temperature when using traditional wet and dry bulb thermometers depends on the state of the equipment. Clean muslin should be used to cover the wet bulb, distilled water should be used in the reservoir, and the bulb itself should be wet.

The instrument should always be placed away from any exhaust vents, any draughts, and all sources of heat to ensure that the readings are accurate. The readings should always be taken on the vessel’s windward side.

A sling psychrometer which also incorporates a wet and dry bulb thermometer can also be used. This gives a more accurate reading as it ensures evaporation takes place during operation when the instrument is whirled around.

Ship Sweat

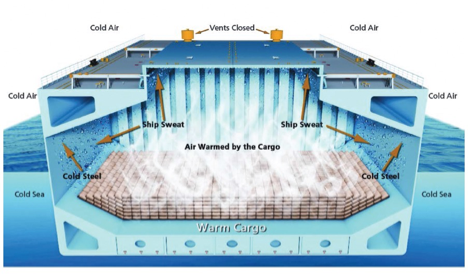

Ship sweat occurs when condensation occurs on the ship’s structure. This happens when the temperature of the ship structures is lower than the dew point of the air in contact with it. This usually happens on voyages from the tropics to the temperate regions.

When a ship loads in the tropics, the air inside the hold is warm and moist. As the ship moves towards the temperate regions, the seas and outside air are cold. The air in the hold still maintains its temperate properties because air is a good insulator. The ship structure, on the other hand, being steel and an excellent conductor quickly takes the temperature of the sea.

If the temperature of the ship structure becomes less than the dew point of the air inside the hold, condensation takes place on the ship structures which might drip onto the cargo and damage it.

Precautions to Restrict Sweat.

To avoid sweat and its effect, it is imperative that wet and dry bulb temperatures of the air are registered and the temperature of air in the cargo compartment taken at frequent intervals, say once a watch. Read the temperature of holds and check its dew point.

Read wet and dry bulb thermometers and find out the dew point of the outside air. Compare the outside and inside temperature and ventilate only if conditions are right. That is by ensuring that any air introduced into the hold will not be cooled below its dew point.

Cargo Sweat.

Cargo sweat is a type of moisture that occurs on cargo. It happens when the cargo temperature is lower than the dew point of the air in the hold. Condensation forms on the cargo as the cargo cools the air it comes into contact with. As a result, direct contact with moisture may cause damage to the cargo.

The most common cause of cargo sweat is improper ventilation of warm damp air into a hold with chilly goods. It’s similar to the condensation that forms on cold beverages can when you remove it from the fridge on a hot summer day.

Cargo sweat occurs usually on voyages from temperate to tropical regions in which cold cargoes loaded in the temperate regions might encounter warm moist tropical air.

Conclusion.

In conclusion, ship and cargo sweat is a serious problem that can lead to damage of cargo and to substantial claims on the ship. However, there are steps that can be taken to prevent and mitigate the problem. By understanding the nature of this problem, ship officers can develop better strategies for preventing and mitigating its impact.

Leave a Reply