Do you get the sense that your boat is gliding through the sea slowly? Something is preventing the propeller’s power flow from being maximised. A cavitation plate could be able to help you accelerate your sluggish boat.

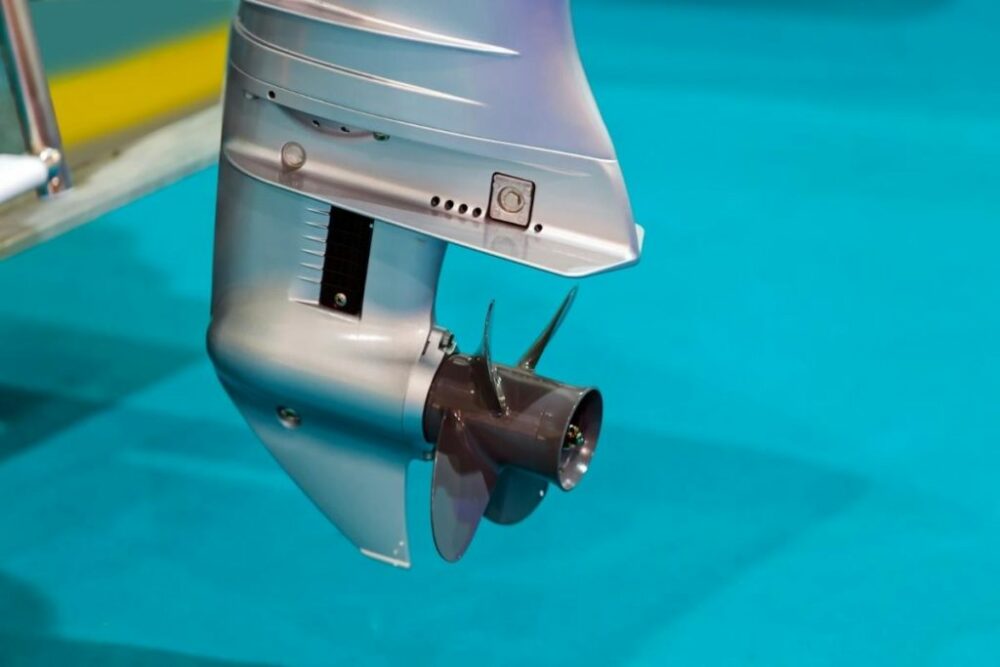

A cavitation plate acts as a planing surface, helping a boat to move through the water more swiftly. This plate must be installed on your boat’s bottom unit to optimise performance.

When this plate is used to trim the motor, the bow response improves significantly. This plate prevents water from entering your prop or intake, hence increasing water pressure.

Cavitation plates are used to improve the performance of boats’ bottoms. They operate as a planing surface, accelerating the ascent of your boat. They increase the responsiveness of your bow while also lessening the stress on your motor. They keep water out of your prop and intake, resulting in increased water pressure.

They assist in preventing “blowouts” during shallow dives. When boats are in motion, the plates’ wings may aid in tracking. Boats of various types will improve to differing degrees. Cavitation plates are often the most advantageous for tunnel hull boats.

Directly above the water level, the cavitation plate should be positioned. If the cavitation plate is submerged, it must be elevated in order to optimise the performance of the motor. If a bracket or Euro transom is utilised, the plate should be positioned 1 inch above the hull every 12 inches rearward.

Continue reading to learn more about cavitation plates, their purpose, how they work, and the several varieties available.

What Is A Cavitation Plate?

A cavitation plate may be advantageous if your boat is sluggish on the water. When a cavitation plate is attached to a boat, it works as a planing surface, enhancing the boat’s ascent to the surface.

Cavitation plates enhance a boat’s bow reaction while also controlling the engine. They work by decreasing the amount of water contained in the prop and intake, hence raising water pressure. The plate must be positioned near the water’s surface to achieve this effect.

If the boat’s plate, on the other hand, is underwater, raising the engine may still increase performance. As a general rule, the plate should be positioned one inch above the boat’s hull for every twelve inches rearward.

Cavitation plates are recommended for use on the bottom sections of boats to enhance performance. It should be parallel to or slightly lower than the bottom of the boat. If the boat’s engine has a short shaft, the vertical dimension of the transom should be around 15 inches.

More exactly, this plate is referred to as an anti-cavitation plate since it aids in reducing the amount of air sucked down from above the propeller of the boat. While it cannot completely eliminate cavitation, it may help lessen its effects.

Cavitation and ventilation both occur in air gaps, resulting in the jittering or hopping of the boat propellers. The vibration occurs as a consequence of power loss, and extreme vibration may cause the propeller to ‘blow out,’ or spin freely.

The most efficient method of preventing cavitation is to trim the motor, which limits the motor’s maximum revolutions per minute or speed. Additionally, this protects the propeller from erosive damage.

This anti-cavitation plate sometimes referred to as a cavitation plate, is a full-wrap device that fully encircles the fin’s anti-ventilation fin. It protrudes forward and drags behind the centre of the outboard motor.

When a propeller generates cavitation in a vessel, the surface of the material is pummelling by impacts from a fluctuating pressure field.

In typical saltwater temperatures, the propeller’s material is ductile, and the first sign of a problem is often the so-called orange peel effect, in which the surface deforms ductile-like, much like the surface of the well-known fruit.

Following that first stage, depending on the severity of the attack, damage may either cease or continue. Microhardness testing of damaged and undamaged blades indicates that when cavitation is applied, the material immediately under the surface work hardens and becomes brittle.

According to the findings, there is very little variation in hardness just under the surface of undamaged blades, which is most likely produced by manufacturing and finishing activities.

On cavitation-damaged blade surfaces, however, a rapid change in hardness may be seen within two cm of the cavitation attack zone. As a consequence, the marine surveyor should predict that the material would fracture brittlely under cavitation attack.

Additionally, investigations show that the local electro potential of the material has a substantial influence on the rate of erosion and damage development.

Why Should You Use A Cavitation Plate?

To fully appreciate the function of a cavitation or anti-cavitation plate, one must first understand cavitation. It is the result of a decrease in the temperature and pressure of the water around the propeller. This situation causes the water to boil.

Bubbles form when the water boils. When these bubbles burst, they create holes in the surface of the propeller. Pitting occurs when small pinholes develop on metallic surfaces.

These pinholes compromise the integrity of metals. When a propeller develops pinholes, the structure of the propeller is weakened, reducing the boat’s performance.

Here, cavitation plates or anti-cavitation plates are used. The basic function of a cavitation plate is to catch water departing or entering the boat’s tube. It prevents air from being sucked into the front face of the propeller or into any other component of the propeller.

When the hull of the boat is planning, water may be seen escaping from the stern. In other words, there is no water around the transom. Additionally, by aligning the cavitation plate parallel to the waterline, the drag is minimised.

However, when submerged in water, this plate generates tremendous resistance. When a boat is driven slowly, especially if it is long and narrow, the propeller often emerges from the water when the boat pitches.

A cavitation plate aids in the direction and retention of water around the propeller blades, hence minimising cavitation. It works similarly to a ski-in that it assists in the faster lifting of the boat’s stern. This enables the boat to execute more precise holeshots, which is beneficial in shallow seas.

There are also cavitation plates with wings available. These plates have been shown to considerably increase a boat’s tracking ability. When different kinds of boats are equipped with cavitation plates, the degree of improvement varies. The greatest gains, however, are seen when cavitation plates are used in tunnel hull boats.

A cavitation plate compresses the boat’s front or bow, aiding it in gaining and maintaining altitude at moderate speeds. As a result, it must be installed at a certain height.

If properly positioned, it will barely skim the surface of the water. It will provide a continuous flow of water to the propeller while preventing outside air intrusion.

How To Install And Use Cavitation Plates

In essence, the cavitation plate must stay immersed in water during the boat’s journey. It should be precisely above the water’s level.

One inch above the boat’s hull for every 12 inches rearward is a reasonable rule of thumb. Some boat dealers position the engine 1/2 inch above the bottom of the hull when it is straight up and down or level.

Lifting the engine to completely submerge the cavitation plate almost always increases performance. Correctly setting the engine’s height has a notable effect.

As a result, the cavitation plate should be parallel to or slightly lower than the bottom. If your boat engine has a short shaft, the transom’s vertical dimension should be around 15 inches.

Due to the varying angles of transoms, running dimensions will differ from vertical measurements. You must verify the distances between the cavitation plate and the inside of the engine mounting bracket.

To properly set the plate, lift the engine about 3/4 inch above or slightly below the keel’s running plane. The vertical clearance of 17 1/2 inches is standard for engines with short shafts.

Cavitation plates are an excellent choice for boats with tunnel hulls, particularly those with fully enclosed tunnels. There are three types of tunnel hull boats:

Full Tunnel: This boat has a tunnel that stretches from under the centre console to the transom through the integrated keel. When the boat is linked to the aeroplanes, this component is utilised to provide water to the propeller.

Additionally, with the addition of a jack plate, this layout allows the boat to function in shallow water.

Half Tunnel: The tunnel begins farther aft in this boat, approximately halfway between the centre console and the transom. It does the same task as the tunnel in its entirety, but with less force.

Pocket or No Tunnel: The tunnel on this boat is most accurately characterised as an indentation. The submerged section at the keel is pan-shaped and reaches around 8 to 15 inches to the bow. Its objective is to reinforce the hull’s stability while also enhancing the boat’s shallow planning capabilities.

Cavitation plates are especially beneficial for boats with complete tunnel hulls since they increase their shallow-water performance. When the cavitation plate is at the rearmost position, it compresses the bow and generates lift.

How To Find The Best Cavitation Plates For You

A cavitation plate may be advantageous if your boat is sluggish on the water. When a cavitation plate is attached to a boat, it works as a planing surface, enhancing the boat’s ascent to the surface.

Cavitation plates enhance a boat’s bow reaction while also controlling the engine. They work by decreasing the amount of water contained in the prop and intake, hence raising water pressure. The plate must be positioned near the water’s surface to achieve this effect.

A cavitation plate acts as a planing surface, helping a boat to move through the water more swiftly. This plate must be installed on your boat’s bottom unit to optimise performance.

When this plate is used to trim the motor, the bow response improves significantly. This plate prevents water from entering your prop or intake, hence increasing water pressure.

To achieve the best performance from your boat, you should use the right cavitation plate. The following guidelines will assist you in choosing the suitable cavitation plate for your boat:

Decide on an Appropriate Size: Cavitation plates are available in four different sizes: large, medium, small plus, and small. Not all cavitation plates are created equal. Certain plates emphasise their universality or “one-size-fits-all” nature.

Lower units are available in a range of configurations and sizes, depending on their horsepower rating and manufacturer. One-size-fits-all plates may become loose and eventually cause damage to a lower unit. Additional plates will need drilling holes in the bottom unit.

Electrolysis happens when stainless steel is bolted through aluminium and exposed to saltwater, hastening aluminium’s degradation. This is also true for cavitation plates made of aluminium.

Certain plates include a narrow border that extends beyond the unit plate’s bottom unit plate. These plates groove the cast aluminium of the bottom unit, thus eliminating the corners!

The vast majority of plates capture enough floating grass to make a salad. It becomes so securely lodged that removing it becomes almost impossible. Certain plates include a “finished” top and an unpolished raw glass bottom. Water flows under, not above, the plate. The garment’s underside should be smooth.

Numerous factors should be taken into account while determining the plate size. Several ideas are as follows:

Large Cavitation Plates – These plates are designed for boats equipped with engines rated at least 115 hp. They provide the greatest planing surface of any cavitation plate currently available.

Furthermore, these plates are often used on vessels with flat transoms. They may be of superior quality if the boat owner so wants.

Medium Plates – These plates are often used on boats with engines producing at least 90 horsepower. They are particularly well-suited for boats with a ‘key slot’ or an inset transom. This avoids the plate from colliding with the sponsons or extensions of the boat while it is turning.

Small Plus Plates – These plates may be acceptable for some boats equipped with 90 horsepower engines. They have a somewhat bigger diameter than the minuscule cavitation plates.

Small Plates – These plates are ideal for boats with engines ranging from 25 to 70 horsepower.

Select a Plate Constructed with Durable Materials: Select cavitation plates constructed of robust materials.

Additionally, some of the strongest plates available are constructed from stainless steel reinforced with laminates, while others are constructed from biaxial glass reinforced with extra laminates on the front. Choose a plate with a high strength-to-weight ratio above a simple mat fibreglass plate.

Choose an Easily Mountable Plate: Certain plates need drilling to be installed. This adds time and work to the process of drilling holes in your boat. Choose a cavitation plate that does not need drilling to attach. These are the self-installing plates.

Select the Most Stunning Plate: Choose a cavitation plate that enhances your boat’s turning capabilities. Additionally, the plate should be strong enough to resist the vibrations generated by the boat’s engine.

Final Thoughts

Cavitation plates are used on the bottoms of boats to increase their performance. They act as a planing surface, speeding your boat’s climb. They provide you with a more responsive bow while also reducing the load on your engine.

They prevent water from entering your prop and intake, which results in greater water pressure.

Cavitation occurs when the pressure on the propeller blades’ backside is significantly decreased. Water vapour bubbles flow into the centre of the blade, where the pressure is higher and the boiling process is stopped. Vapour bubbles collapse against the blade’s surface.

To reduce the chance of cavitation developing in marine propellers, a set of nozzles is put on the ship’s hull just ahead of the propeller. These nozzles squirt compressed air onto the propeller, forming a “macro bubble.” For more information refer to the article on how to reduce propeller cavitation.

Cavitation plates are recommended for placement on the bottom sections of boats to help in performance enhancement. It should be almost parallel to or slightly lower than the boat’s bottom. If the boat’s engine has a short shaft, the vertical dimension of the transom should be around 15 inches.

For short shaft engines, the industry-standard prescribes a transom height of 15 inches. A long shaft engine requires a transom height of 20 inches, while an extra-long shaft engine requires a transom height of 25 inches. While this is true, some saltwater motors reach a length of 30 inches.

To expedite the process of bringing your boat to the top, you must use a cavitation plate, which works as a planing surface. By placing this plate on the bottom unit of your boat, you may improve its performance.

If you install this plate on your boat, you may notice an increase in bow response while changing the engine. It will maintain a low water level at the prop and intake, which will result in higher water pressure.

By connecting a hydrofoil to the cavitation plate, you may boost its speed and stability (performance stabiliser). Simple to install, these hydrofoils boost your boat’s top speed and help you save money on fuel costs:

Hydrofoil SE 400 Sport: The SE 400 Sport Hydrofoil’s compact streamline design enables rapid, accurate handling. Since the cupped bottom and downturned trailing edge have been removed, there is no drag.

Sting Ray XRII Senior Hydrofoil: The Sting Ray XRIII has a sleeker, more aerodynamic design for the quickest hole shot ever. This one-of-a-kind design is inspired by the tunnel-prop technology used by offshore superyachts. The XRIII harnesses the power of the prop wash to increase thrust.

You’ll benefit from increased performance and fuel efficiency. Additionally, the XRIII has a three-point locking mechanism with a vice-block design that avoids the need for drilling. There will be no quantification in the future.

There will no longer be any accessible templates. No more engine damage will occur. For engines with a maximum output of 300 horsepower.

Leave a Reply