Whenever cargo has to be loaded on or discharged from a vessel, the vessel has to be parked and fastened to a quay, wharf, pier, or jetty with mooring ropes to facilitate safe operation.

The berthing of a ship is the process of bringing a vessel to a designated location, such as a quay, wharf, pier or jetty, and securing it in place. The location where a ship is berthed is known as a “berth.” A ship can be berthed port or starboard side on or bow or stem on. The term “berth” also refers to the specific location where a vessel is moored or anchored.

A vessel can berth port or starboard side, with no wind or tide, with the tide ahead, and with the wind onshore or offshore. Berthing operations become easier however with the vessel stemming the current or tide, whichever is stronger moving against the direction of the current and with the wind onshore as this way ensures the elements provide a braking effect.

Maneuvering and controlling the vessel with engines, helm movements, and tug assistance are all part of ship handling operations.

Berthing and unberthing maneuvers necessitate extensive knowledge and skill on the part of the master, officers, and crew, as well as excellent teamwork with the mooring party ashore.

The master, pilot, and tug masters must be well acquainted with local tides, wind conditions, depths, and navigation aids, but they must also consider the maneuvering characteristics of the vessel such as the transverse and axial thrust of the propeller, how the ship responds to the rudder, and how much power she develops when running astern.

The term “berth” can refer to the quay, wharf, pier, or jetty where a ship comes alongside, but it can also refer to a location where a vessel is moored or anchored.

Types Of Berthing Structures

Berthing structure is a general term used to describe a marine structure for the mooring of vessels engaged in cargo operations. They provide a vertical front that allows safe and secure mooring that can then facilitate the unloading or loading of cargo or people from vessels.

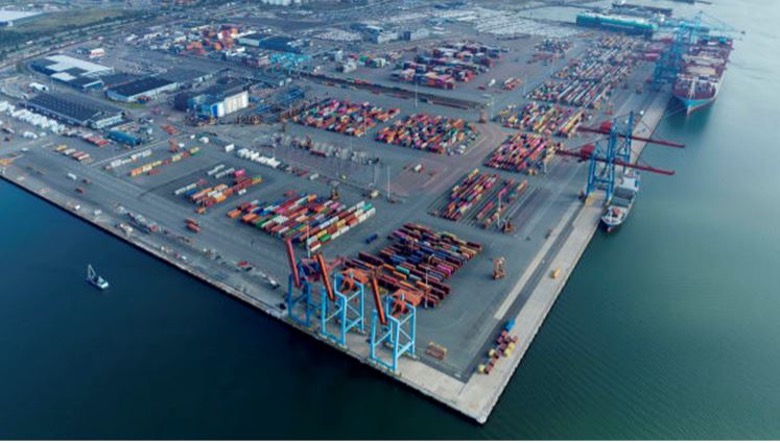

Berthing structures are ideally located in the most sheltered part of a harbor or along the lee side of breakwaters. Berth are classified according to how they are constructed, the type of cargo they are expected to handle, and how they are connected to the nearby landmass. Let’s take a closer look at some of them.

By Construction

These berths are distinguished by the physical methods used in their construction. The 2 main types are Solid Structure Berths which are characterized by solid vertical piles that have filler material. They are usually constructed by the use of a gravity wall structure.

The other, Open Structure Berths are characterized by structures that are supported by piles set slightly offshore from the natural extent of the land. Offering high flexibility they however cannot hold too much weight and are therefore limited by the weight of cargo that can be supported by the berth.

By Cargo

These berths are distinguished by the type of cargo they are built to handle. While there are several types-as there are several types of cargo the 3 main types are Container berths, Bulk berths, and General berths. Container berths are berths where container cargo operations take place.

Such berths are usually fitted with specifically designed cranes for particular tasks. With the rapid increase in the size of containerships, these berths are now becoming bigger.

Bulk berths are specially used for handling dry or liquid bulk cargo. Ships that use such berths use pipelines, excavators, or conveyor belts for cargo operations and cargo is usually stored alongside the berthing area e.g. stockpiles.

By Shore Connections.

These berths are distinguished by how they are attached to the shore or the absence of such attachment. There are 2 types – Finger pier berths that are attached to the shore by a narrow fingerlike structure hence the name.

They offer a greater berthing area per length of waterfront and are specially used for small to medium vessels generally passenger ships.

The other type, Offshore Berth comes into practice for precarious cargo handlings such as hydrocarbon oils and gases. This type of berth is situated far from the shore for safety reasons. They have special structures that are termed DOLPHINS for securing vessels. They may be fitted with bollards and fenders according to the configuration of the vessels that are brought in for berthing.

Ship Berthing And Unberthing Procedures

Berthing is the process of bringing a vessel to her berth until she is made fast. Although berthing operations are carried out together by the master of the ship with advice from the pilot and assistance from tugs, maritime tradition always considers this operation as strictly a responsibility of the shipmaster.

As such there are certain actions – the so-called golden rules of berthing- that a Master should always take before and during berthing. The master should always identify probable dangers that are likely to be encountered during the berthing/unberthing operations and how to mitigate them.

The master and pilot exchange information on their respective expertise master gives the pilot information about his vessel regarding maneuvering characteristics of his own vessel while the pilot briefs the master on the local conditions and how the berthing/unberthing operation will be carried out. This phase is referred to in maritime operations as passage planning.

The situations as to how the berth is approached/departed will be different depending on a lot of factors such as the under keel clearance, weather, wind, current, tide, available berth length, and distances to the vessel’s forward and aft from the berth, size of the harbor basin, etc. Based on these factors the maneuvers and combination of tugs’ usage can be made

Approach the berth at an angle of around 200 and a speed of about 2 knots. Tug usage will usually depend on the requirements of the port authority based on the difficulty, the location, general weather conditions, etc., and the availability of bow thrusters on the vessel.

If possible turn on the berth to stem the tide or current whichever is stronger. Tugs are usually made fast before commencing any berthing manoeuvers with the forward tug holding the bow from fouling the jetty while the aft tug pushes the vessel towards the jetty.

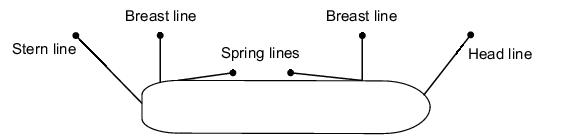

Using the engines, tugs, and mooring lines the vessel is drawn alongside the jetty and secured by mooring lines, usually three sets at each end – at the bow headlines, forward breast lines, and forward back springs. At the stern, there are stern lines, aft breast lines, and aft back springs.

Berthing Area on a Ship

A berthing area on a ship is a portion of the ship that has bollards, and mooring winches and where the mooring ropes are fastened and is useful for the process of ship berthing.

On most ships, these areas are the forecastle at the ship’s bow referred to as “fo’c’s’le” in seamanship, and the poop deck. These areas house the equipment used for berthing and therefore receive special care like anti-slip paint etc, etc

Nowadays there are various electronic berthing aids that provide information during a vessel’s approach and final berthing maneuvers. The information that is usually of most value, particularly for very large vessels, is speed over the ground since it is critical to maintaining the kinetic energy of such vessels below that which can be absorbed by the berth. Since this requires a skilled judgment of velocity.

These modern systems guarantee a more safe mooring. By featuring critical information in the real-time display of vessel approach speed and distance, combined with suitable alarms, these modern large ships can safely carry out berthing operations in all kinds of weather.

Difference Between Berthing And Mooring

Berthing is the mooring of a ship within an allotted space at a pier, quay, or similar fixture. Mooring is securing a ship by ropes or chains (cable) to a fixed object. For example a, vessel moors at a buoy or uses a Mediterranean moor to secure a berth.

Difference Between Docking And Berthing

Docking is the mooring of a ship to a pier, quay, or similar fixture while berthing in the mooring of a ship within an allotted space at that pier, quay, or similar fixture. Think of a dock as an entire parking lot, with a berth being an individual parking space within that parking lot.

Leave a Reply