The bilge system is provided in the ship to remove bilge water from the ship’s dry compartments in emergencies. The major uses of the system are for cleaning water and oil which accumulates in machinery space bilges as the result of leakage or draining, and when washing down dry cargo holds.

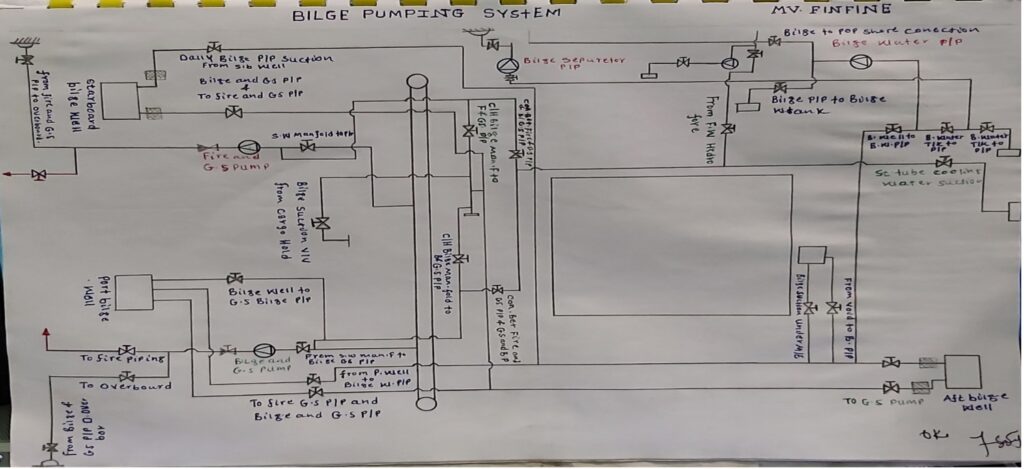

The bilge main in the engine room has a connection from dry cargo holds, tunnel, and machinery spaces. Bilges are the lowest part of the ship, the water which collects in this area is called bilge water.

How does the bilge system work?

Small amounts of dirty water that have leaked or condensed into a dry space are removed using the bilge system. Machinery areas, cargo holds, cofferdams, voids, stores, tunnels, and pump rooms are all served by this system. Although each area has its own pipes, the pump is most likely shared.

The number of pumps and their capacity is determined by the vessel’s size, kind, and service. All bilge suctions must have suitable strainers, which in the machinery space would be mud boxes at floor plate level for easy access. The bilge would be reached through a vertical drop pipe.

Why is it important to remove bilges?

All ships traveling and working on international seas are required to follow the maritime authorities’ international codes and agreements. For this, ships should be maintained at a particular standard by the combined efforts of flat states, shipping companies, and shipmasters.

In port state inspections, dirty engine room bilges are one of the most common detainable infractions. In the ship’s bilge management, clean bilges are the first line of defense against marine pollution.

The engine room bilges on most ships have oily water. This is because leaks from various machinery and systems eventually make their way into the bilges. The oily bilges should never be pumped directly overboard.

On most ship today, the engine room bilges, usually located at the 4 corners of the engine room, is first transferred to a primary bilge holding tank. Here they are allowed to settle and the separation of oil takes place by gravity.

The tank is also heated with steam, which helps with separation. Oil is skimmed to the top or drained to the sludge tank. The water is pumped into the ship’s main bilge storage tank. The bilge water is then discharged overboard via the oily water separator, with an oil concentration of no more than 15 ppm in the affluent, or discharge water.

The separated oil from the oily water separator is discharged into a sludge tank. Sludge tanks are storage tanks for oily water with a high percentage of oil and little water. The sludge pump transfers the oily sludge to the incinerator waste oil tanks after which they are incinerated in the waste oil incinerator.

What Are The Components Of The Bilge Piping System?

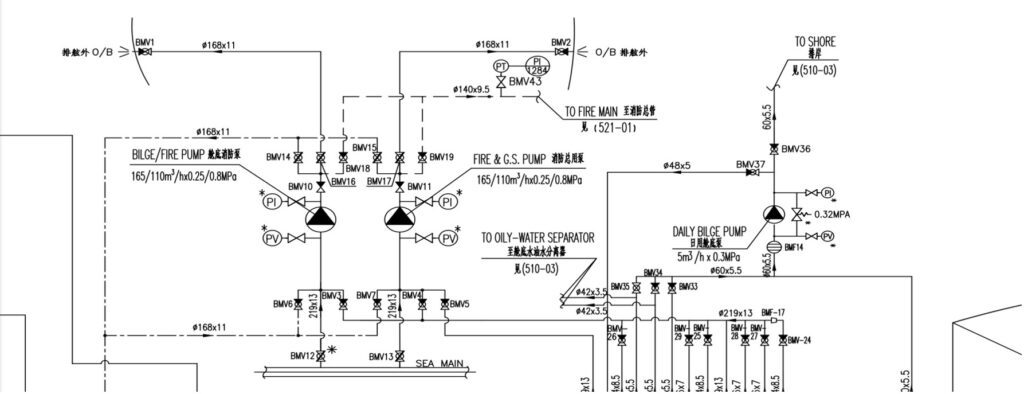

A series of pipelines connect the bilge pumps to the bilge system. This bilge piping system includes:

- Pumps: A bilge pump found on a ship is generally a reciprocating type or centrifugal type. The reciprocating type pump provides a slower rate of flow than the centrifugal type of pump. Also, the mechanism and construction of a reciprocating pump are extremely complicated for a pump used for such an important purpose. Due to these drawbacks, the use of reciprocating pumps is getting reduced day by day, nowadays centrifugal pumps are generally used as bilge pumps, due to their pumping process taking less time and having a higher production rate. It pumps bilge water from various locations in a vessel like an engine room bilge well, cargo holds bilges, etc… to the bilge holding tank and during an emergency overboard. Since fuel can be present in the bilge, these bilge pumps are designed to not cause sparks. Electric bilge pumps are frequently equipped with float switches that activate the pump when the bilge reaches a predetermined level.

- Tanks: tanks store bilge water and help to separate oil from the water by settling and heating

- Pipelines: lines carry and transfer bilge water between tanks and pumps. Lines should be checked regularly for leaks, corrosion, and obstructions.

- Valves: valves control the flow of water into or out of tanks or lines. They also control pressure in tanks by regulating the flow to the pump.

The piping of the bilge main in the engine room has connections from dry cargo ship holds, pipe tunnels, and machinery spaces. The number of pumps required to be fitted for the bilge system, their capacity and flow rate, and the sizes of the main pipe and the branch pipes is all regulated under SOLAS regulations and vary depending on the size and type of ship.

In merchant ships, there will be three pumps connected to the bilge main. These are the fire and bilge general service pump and the auxiliary bilge pump. Additionally, these pumps have direct bilge suctions to the engine room’s port, starboard, and tunnel wells, respectively.

What Is A Reciprocating Pump And How Does It Work?

A reciprocating pump is one type of positive displacement pump and its displacement pumping action is achieved by the reduction or increase in the volume of a space causing the liquid or gas to be physically moved.

The method used is either a reciprocating piston in a cylinder, or a spinning unit using vanes, gears, or screws. These pumps convert mechanical energy into pressure energy. It is used for high head and small discharge.

What Is A Bilge Ejector?

Bilge ejector is liquid jet pumps that use water or other liquids under pressure to create a pumping action. It is based upon Bernoulli’s principle which states: ‘when the speed of a fluid increases its pressure decreases and vice versa.

The ejector pump uses the venture effect of a converging nozzle to increase the water velocity to transform high static pressure into velocity pressure. In a standard bilge ejector, the drive pressure liquid discharges through a single nozzle to start the pumping action. It is self-priming and can handle liquid and solid mixtures.

There are no moving parts to break down or wear out. A bilge ejector is used to pump bilge water from chain lockers, bilges, cargo holds, or any space that has to be pumped dry.

Ejectors are simple in design and reliable in operation since there are no moving parts, no lubrication is necessary and maintenance is minimal. Bilgewater ejectors depending upon their application can be manufactured out of various materials ranging from bronze, steel, and stainless steel with nozzles usually being made of high-grade stainless steel.

What Is A Mud Box On A Ship?

The mud box is an important component in a vessel’s bilge system. It is a coarse strainer with a straight tailpipe down to the bilge. A mud box is fitted at the ends of the bilge lines to stop debris from being sucked into the bilge pipeline.

This mud box enables the internal perforated plate to be cleaned when necessary, and the lid of the mud box is easily removed without disconnecting any pipework. The requirement for bilge systems on ships carrying dangerous goods is basically the same as for cargo ships.

Systems pulling fluids from gas-hazardous spaces, on the other hand, are maintained separately from systems supplying gas-safe places, with their own pumps and pipes.

What Is The Difference Between Bilge And Ballast?

Bilgewater is wastewater produced by numerous operations involved in keeping a ship running while at sea and is found low down in the machinery compartments of most ships.

Bilgewater must be treated with caution because it may contain amounts of various industrial fluids such as coolant, lubricants, and fuel from the ship’s machinery areas. As mentioned above the essential purpose of a bilge system, is to clear water from the ship’s dry compartment in an emergency.

The system is primarily used to clear water and oil that collects in machinery area bilges as a result of leaking or draining, as well as for washing down.

On the other hand, ships are provided with tanks that can be filled with seawater if required to provide stability to the ship, correct the list, and trim the ship. These tanks are called ballast tanks.

A system of pumps and piping has to be provided to fill or empty these tanks when it is required. This system is called the ballast pumping system. Ballasting and de-ballasting the ship are the two main processes in the procedure.

Ballasting is the process of taking seawater into dedicated tanks to maintain ships’ stability; while de-ballasting is pumping water out of those tanks for the same reason. Screw lift valves are installed in the ballast pipework so that seawater can be filled and emptied from purpose-built tanks.

But the bilge system is fitted with screw-down non-return valves to prevent any flooding back to the compartment served and also fitted with strainers or mud boxes at the bilge wells to make the system free of solid remains.

Leave a Reply